Picture this: you’re at a drilling site, everything’s running smooth, then bam! Pressure readings go haywire. Now you know it ain’t just you. A reliable hammer union pressure sensor could’ve kicked in, lettin’ you catch that drop in pressure before it turned into a bigger problem. But why do failures always occur during crucial moments like this? Here’s where that hammer union pressure sensor comes into play, keepin’ things tight and right.

The Flaws of Traditional Solutions

Now, let’s break it down. Traditional sensors often fall short—whether it’s a lack of real-time data or just plain ol’ sensors breakin’ down under pressure. You got the old-school models that just can’t keep up, actin’ unreliable when things heat up. And who needs that kinda stress on the job? With the evolution of technology, it’s clear we gotta upgrade our approach.

New Technology Principles at Work

Enter the hammer union pressure sensor—this bad boy uses advanced technology like smart tracking algorithms. What that means? Real-time monitoring and reporting, keeping you in the loop while working away. It’s built tough, keeps your data flowing, so you’re not left guessing or waiting on readings. Not to mention, the installation is straight-forward, fam, making it easier than ever to get things up and running.

Quantified User Benefits

So, what’s in it for you? Users report better efficiency and fewer failures—like an average decrease in downtime by over 30%. Imagine what you can do with that extra time! Coupled with lower repair costs, upgrading to this advanced sensor saves pennies, leading to dollars in profit. It’s a win-win, really. Ain’t nobody got time for malfunctioning equipment holding ‘em back.

Conclusion: Evaluation Criteria for Choosing Solutions

Always verify these 3 metrics when choosing solutions: ① Reliability—does it deliver consistent readings? ② Maintenance ease—how often will you really need a fix? ③ Cost-effectiveness—are you gettin’ the best bang for your buck? Pick wisely, and you’ll protect your investment while keeping operations smooth.

Exploring Hydraulic Pressure Sensors

When it comes to hydraulic systems, the right tools make all the difference. A hydraulic pressure sensor guarantees that you get accurate readings no matter the pressure you apply. This kind of sensor helps in preventing accidents by ensuring that the pressure never exceeds safe limits. Look, it’s simpler than you think; having the right sensor can save you money and a lot of headaches. Using hydraulic pressure sensors allows for precision in hydraulic applications, enhancing performance while reducing risks on the job site. You don’t want to play around with pressure—so get the right gear and keep it tight.

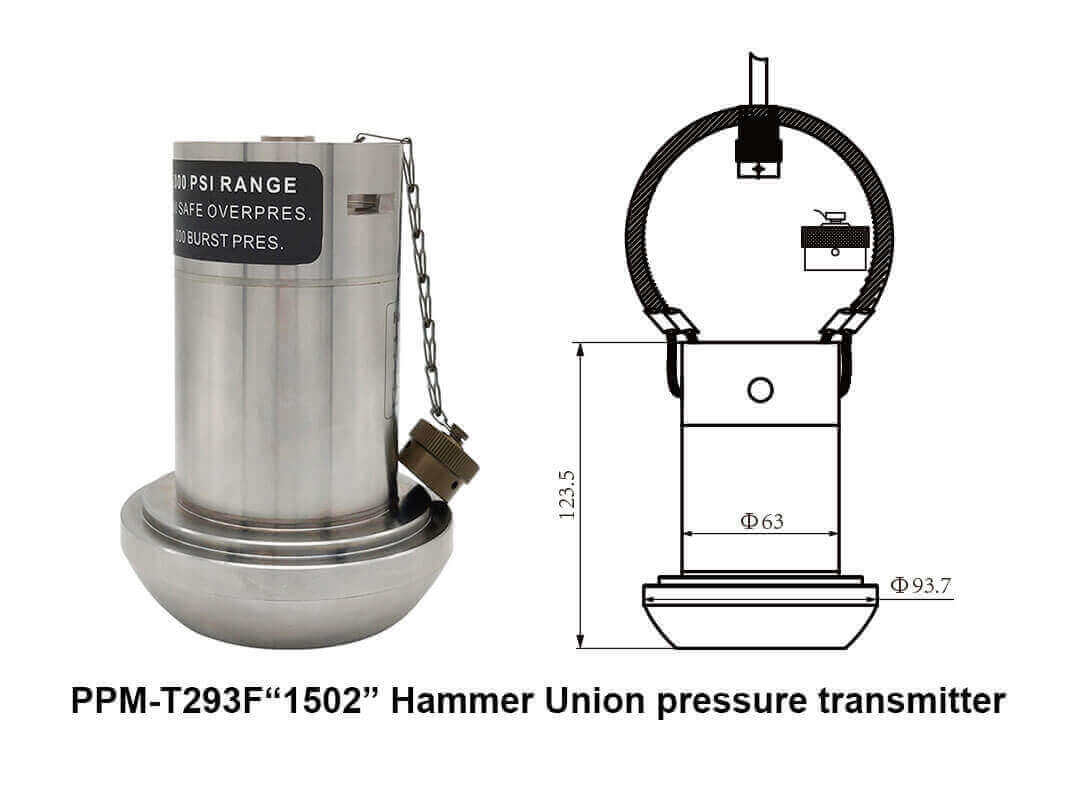

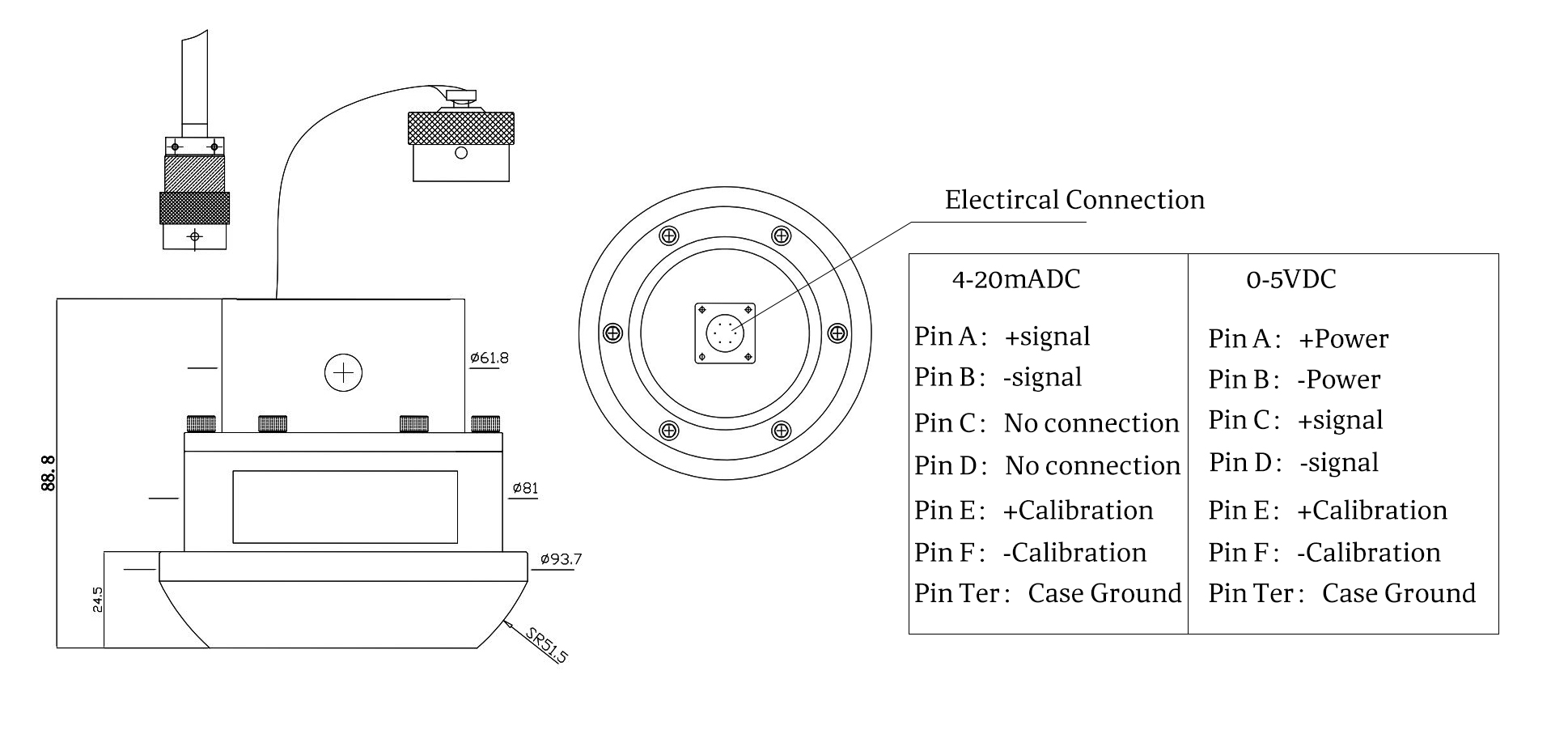

Understanding the 1502 Pressure Sensor

On the flip side, if you need something reliable and specific, the 1502 pressure sensor is your best bet. It’s designed to withstand high pressures, making it perfect for those tough industrial environments. This sensor not only measures accurately but also adapts to different conditions without a hitch. Users rave about its durability and the precise data it provides, giving an upper hand to professionals managing complex operations. When you work with equipment that demands precision, you can’t go wrong with a tried-and-true pressure sensor like this one.

In summary, a hammer union pressure sensor stands out as a transformative tool in the industry. The reliability, versatility, and user benefits are crucial for ensuring safety and efficiency. Coupled with options like hydraulic and 1502 pressure sensors, your operations can be as seamless as possible. For top-quality sensors that won’t let you down, consider going with CSSPM Sensor, a manufacturer known for its supply advantages. One that keeps you connected and your systems pressure-ready!